Home > Our Impact > Industry

Industry

Globally, industry is the largest fossil fuel consumer among all end-use sectors—and hence, the largest emitter. What’s more, industrial facilities are built to last decades. Many production plants built today probably will be able to operate through 2050 and beyond. Fortunately, there are solutions: new technologies are already feasible, and in applications where breakthroughs are still on the horizon, production plants can at least be made ready today for a future retrofit compatible with climate neutrality. And it’s not just about energy: industry uses fossil fuel as a feedstock for everything from plastics to ammonia production.

Emissions peaking and reduction targets that include industrial sectors

Carbon peaking and reduction targets provide a long-term framework for governments, businesses, and organizations to work toward, driving innovation in renewable energy and climate-neutral industrial processes. As products of industrial goods are globally traded, targets for both the overall industrial sector and subsectors create opportunities to align strategies, harmonize policy, and advance strategic cooperation. Sector-specific carbon targets are instrumental because they address sectors’ unique challenges and opportunities, allow for nuanced emissions reduction strategies, and provide a benchmark for measuring policy progress. Targets must be underpinned by concrete policies to maintain credibility, and political follow-up action is critical when a target is missed.

Policy spotlight

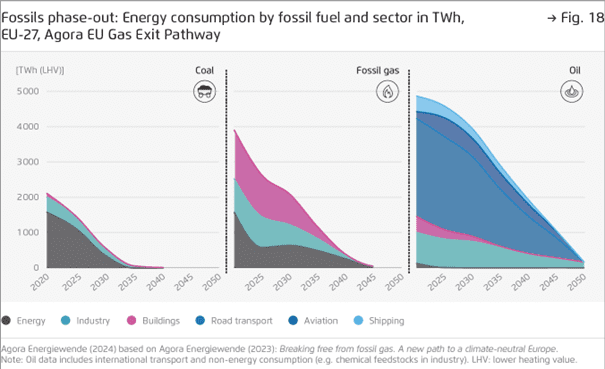

The EU Emissions Trading System foresees a gradual reduction in the free allocation of emissions certificates. It thereby provides a clear pathway of emissions reductions for industry. In combination with the introduction of the EU’s carbon border adjustment mechanism, it incentivizes industry to abandon the use of fossil gas by 2040.

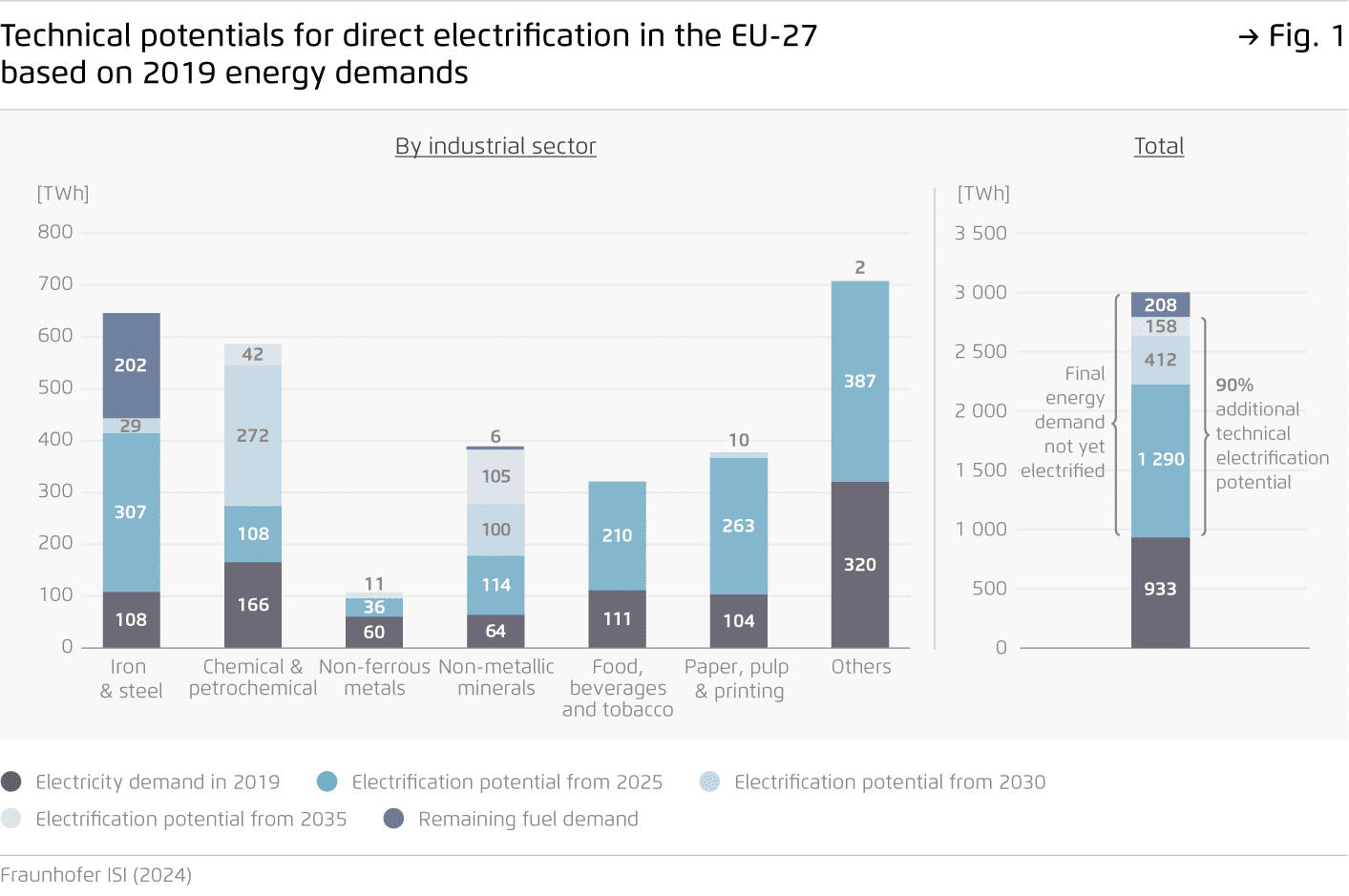

Policies to promote electricity and hydrogen use

All industrial processes require both energy and feedstocks, which rely today on fossil fuels. Industrial emissions can be lowered by direct and indirect electrification that is powered by renewable energy sources. Direct electrification is preferable where feasible, due to its greater efficiency. Examples include using heat pumps to provide low- to medium-temperature industrial process heat, and using power-to-heat technologies to provide higher temperatures. Where direct electrification is not feasible, an option is indirect electrification—producing green hydrogen from electricity via electrolysis. Direct and indirect electrification policies are essential to close the cost gap with fossil-based technologies and to promote the use of green electricity and hydrogen in industry. Policies should promote the large-scale deployment of renewable energy sources to provide the necessary electricity and overcome cost barriers.

Circular economy solutions to drive use of low-carbon materials

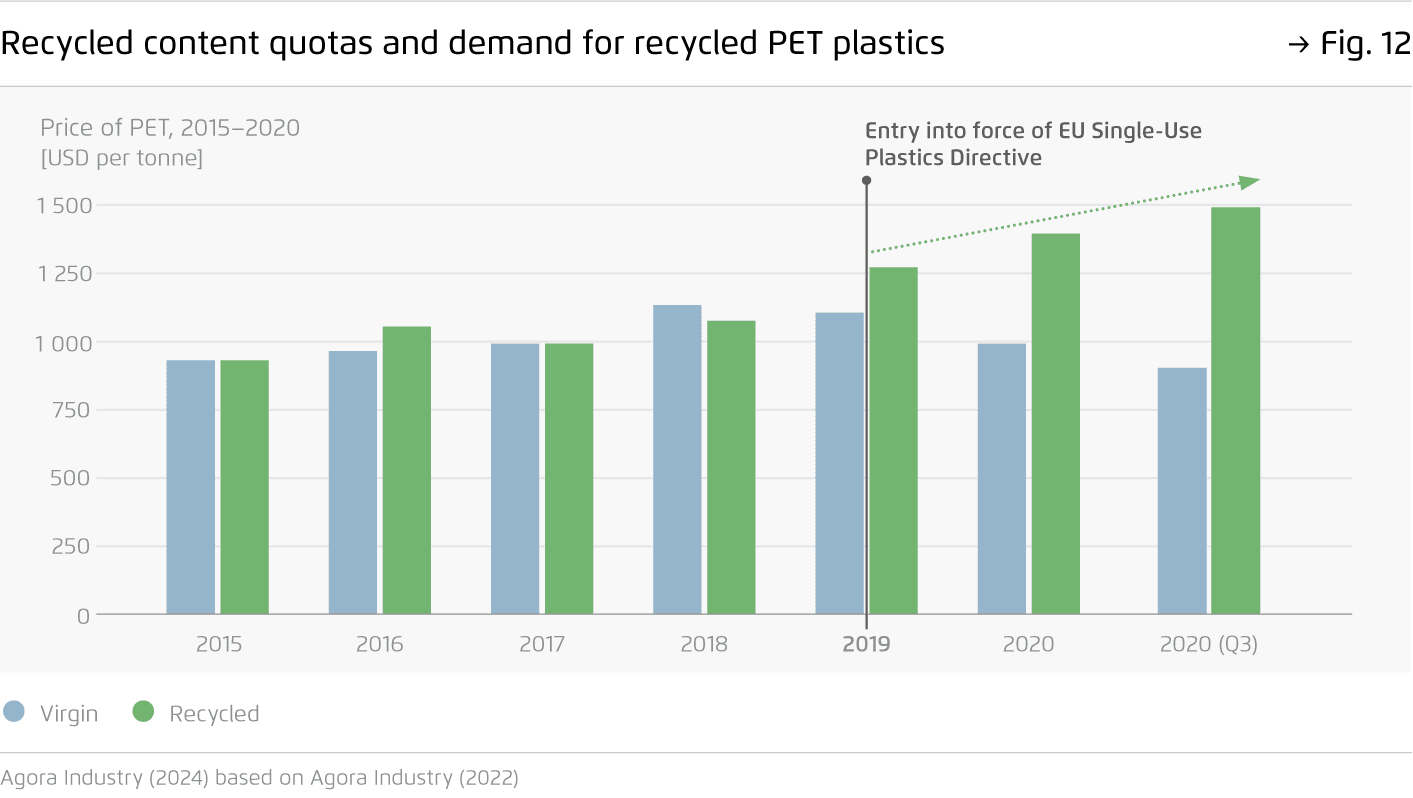

GHG emissions resulting from manufacturing processes and at the end of life for products are often hidden from customers, while emissions-related regulations primarily focus on the energy consumption directly associated with the use of appliances, vehicles, and buildings. But without reducing emissions associated with the production and end-of-use phases for goods, climate neutrality cannot be achieved. Embodied carbon regulation—a set of rules that can slash carbon emissions from the entire life cycle of a product—is required to comprehensively limit emissions related to the use of goods. Key rules entail ensuring information transparency for consumers, stimulating material efficiency and the circular economy, and creating a market for sustainable products.

Policy spotlight

The European and German circular economy strategies emphasize a complete list of regulatory areas that need to be adjusted to incentivize higher recycling rates, material efficiency, and substitution. For example, recycling content quotas in the EU have helped reduce demand for virgin plastics.

Policies to push lab-scale technologies up the commercialization curve

New clean technologies that can replace fossil fuel-based processes in heavy industry can fail before they reach the market if researchers do not have enough funding to refine prototypes, conduct rigorous testing, and develop efficient production processes. By investing in research and development, governments can ensure that transformative technologies reach their full commercial potential, attract additional private funding, and drive competitive advantages in the global marketplace. Tax incentives, depreciation schemes, and subsidies can further help first-mover companies invest in clean technologies that can’t yet compete on cost with fossil fuel-based technologies. Early adopters can also serve as “real-world laboratories,” enabling policymakers to observe new technologies in action, assess their implications, and develop adaptive regulations that support innovation, while ensuring safety and compliance.

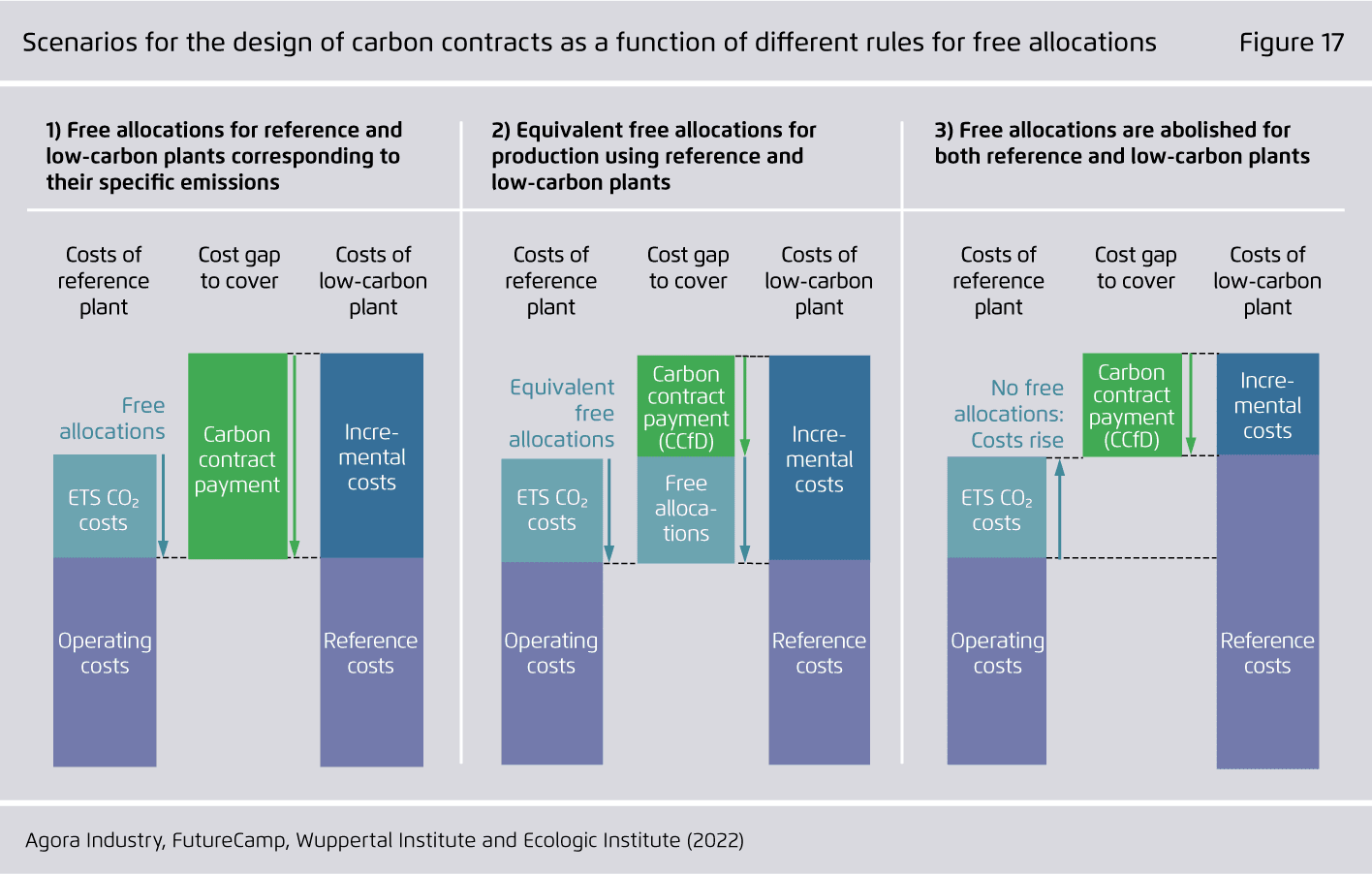

Policy spotlight

The South Korean and German carbon contracts for difference (CCfD) schemes provide financial security to companies to make early investments in climate-friendly material production. CCfDs compensate for higher abatement costs during periods when carbon prices aren’t sufficiently high. CCfDs thereby ensure the initial supply of low-carbon materials until demand-side instruments kick in.

Ensuring equity

Clear strategies to address impacts on workers and communities are key if the industrial transformation is to receive widespread support. This means engaging with employers, labor unions, and other stakeholders to ensure a just transition that doesn’t leave disadvantaged groups behind. Broad participation is essential, as are measures tailored to specific regional and political contexts.